Oil seal introduction

Time:

2020-09-28 11:21

Source:

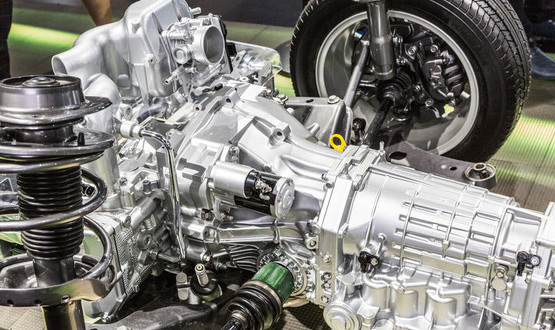

Pingxiang Rubber and Plastic Products Factory is a rubber products company specialized in the research, development, production and sales of rubber products. Located in Huangcun Industrial Zone, Pingxiang County, Xingtai City, the company mainly engages in three leading industries: rubber seals, automobile rubber parts, and engine support.

The optimization of rubber and plastic products manufacturers is often used for metal parts and concrete structures with large rigidity, while the rubber and plastic products materials have small rigidity. The optimization of rubber and plastic products manufacturers' material reduction behavior has a great impact on the overall performance of components, so it is necessary to verify and analyze the optimization structure of rubber and plastic products manufacturers. In order to improve the accuracy of finite element verification analysis, the smooth tread used in the optimization process of rubber and plastic products manufacturers was replaced by the common tread pattern of 11.00R20 radial truck tire.

According to the static load grounding condition analysis of the non-pneumatic tire optimized by the rubber and plastic products manufacturer, due to the poor convergence of the calculation, it can only be calculated that the non-pneumatic tire bears a load of 24.38 kN (the standard load of the same size truck tire is 34.79 kN), at which time the tire's sinking is 79.06 mm. At this time, the displacement and deformation distribution of the non-pneumatic tire is shown in Figure 3-5. The lateral displacement of the support structure is too large, and the tire body contacts with the wheel thickness, which affects the further deformation of the tire.

The stress distribution of the non-pneumatic tire optimized by the rubber and plastic products manufacturer under the static load grounding condition is shown in Figure 3-6. At this time, the maximum stress borne by the tire is 48.22 MPa, which exceeds the common stress range of rubber and plastic products (15-30 MPa) 69. The support of the non-pneumatic tire will be damaged. It can be seen that this tire structure cannot meet the load bearing requirements.

The grounding pressure distribution of the non-pneumatic tire optimized by the rubber and plastic products manufacturer under static load is shown in Figure 3-7, and the gray part is the non-contact part. The maximum ground pressure of the non-pneumatic tire model is 3.41 MPa, and the ground pressure is mainly distributed near the centerline of the tread, with obvious stress concentration. This shows that the non-pneumatic tire only contacts the center of the tread with the ground, and the tire shoulder does not contact the ground. The tire ground area is small, the unit ground pressure is large, and the load distribution is uneven, which will lead to uneven wear of the tire during driving and affect its driving mileage.

key word:

Related news

Sep 28,2020

Sep 28,2020

Sep 28,2020